ZF Innovations for all Vehicle Categories

2009-09-22 Source:www.zf.com

At the IAA 2009, ZF presents how it has adapted its leading driveline and chassis technology to the changed market requirements. Transmissions, steerings, and axles by ZF in smaller vehicles with state-of-the-art engines can also contribute to considerable fuel and emission savings by means of smaller dimensions, power-on-demand solutions, and lightweight design.

Downsizing is not only a keyword for engine development. ZF's driveline and chassis technology can also be adapted to smaller vehicle categories. At the IAA 2009, ZF presents its product range for this trend, consisting of damper technology, multi-ratio transmissions for front-transverse drives, steering technology, as well as a lightweight chassis design.

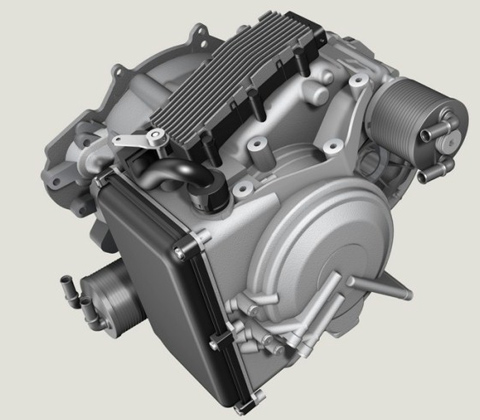

ZF hybridizable multi-ratio transmission

Damper technology for all applications

The ZF Powertrain and Suspension Components division has realigned its damper portfolio. The basic technology is available with the designation "Basic"; it offers the essential functions of a monotube damper as well as standardized connection interfaces for various vehicle categories – among other also for small mid-size cars. If this basic technology is to be adapted to vehicles or special installation cases, it is offered as a "Customized" range. Automotive manufacturers will be able to order individual damper technology for special requirements as "Advanced" technology: For example, this would include the individually adapted electronic damper system CDC (Continuous Damping Control) including the control electronics and software. The same ranges are also offered in a second product line called "Eco". It focuses on a lightweight design for lower weight – by using aluminum, high-strength steel, or the optimal component design in engineering/construction, for example.

Automatic transmissions for front-transverse drives

At the IAA 2009, ZF for the first time exhibits a multi-ratio transmission for vehicles with front-transverse drives. It is adapted to mid-size vehicles and smaller vehicle categories. Currently, ZF is working on an entire, modular front-transverse kit which can also be used with hybrid variants. The results of the development will probably be ready for volume production in 2013. It aims at extending the transmission portfolio by a front-transverse product line that contributes to fuel and emission savings also in lower torque ranges and which can be offered as a hybrid variant without necessitating major conversion activities.

Less complexity in the chassis

It is also possible to save weight in the chassis – and that even makes a lot of sense: If the chassis weight is reduced, lower engine power suffices to achieve the same performance as a car with a conventional chassis. Moreover, fewer unsprung masses considerably improve the vehicle's dynamic and comfort characteristics. In the past few years, however, the trend pointed into the opposite direction: Increased demands for driving dynamics, safety, and comfort made car chassis constructions more and more complex and heavier - more structural components, new axle designs, integration of active suspension components.

The "Multi Compliance Twist Beam Axle" (MCT) by ZF points into another direction. The aim was to develop an innovative, minimum-cost rear axle design based on a twist-beam rear axle which basically features the same performance as a multilink rear suspension when it comes to kinematic and elastokinematic characteristics - without being significantly more expensive. Due to the separation of functions, the multilink rear suspension allows for a targeted design of chassis-specific characteristics and thus clearly stands out from the twist-beam rear axle. The MCT axle can now bridge the gap between the classical twist beam rear axle and the multilink rear suspension.

SMiCA (Sheet Metal integrated Control Arm) proves that ZF is offering mature lightweight solutions in chassis technology - already today. The control arm from ZF's Car Chassis Technology division requires no rivets or screw connections. This makes it lighter than conventional sheet metal control arms. Moreover, it requires less installation space and allows for more freedom when designing the chassis.

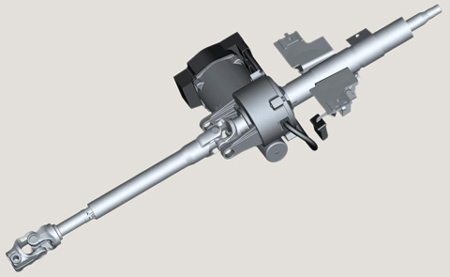

The smart steering system that generates savings

With the "Column Type" solution where the servo unit is integrated in the steering column to save space, ZF Lenksysteme also makes the benefits of its electric power steering system available for smaller mid-size cars. In contrast to hydraulic power steerings, this electromechanical steering system also only consumes energy when the driver is actually steering. This leads to fuel savings of approximately 0.4 liters per 100 kilometers in the NEDC driving cycle (New European Driving Cycle) and up to 0.8 liters per 100 kilometers in city traffic compared with conventional power steering systems. As soon as the driver performs a steering motion, the corresponding steering torque and speed are registered by sensors. From this data, the control unit computes the required steering support within milliseconds and a servomotor transmits the optimal servo torque to the steering column via a helical gear drive. The "small" Servolectric is designed for steering axle loads of up to 1,000 kilograms. Since less steering forces have to be mastered in lighter vehicles, the amperage is also significantly lower, e.g. when parking.

ZF Column-type solution

Views:0Editor:ZF

Related China Bus News